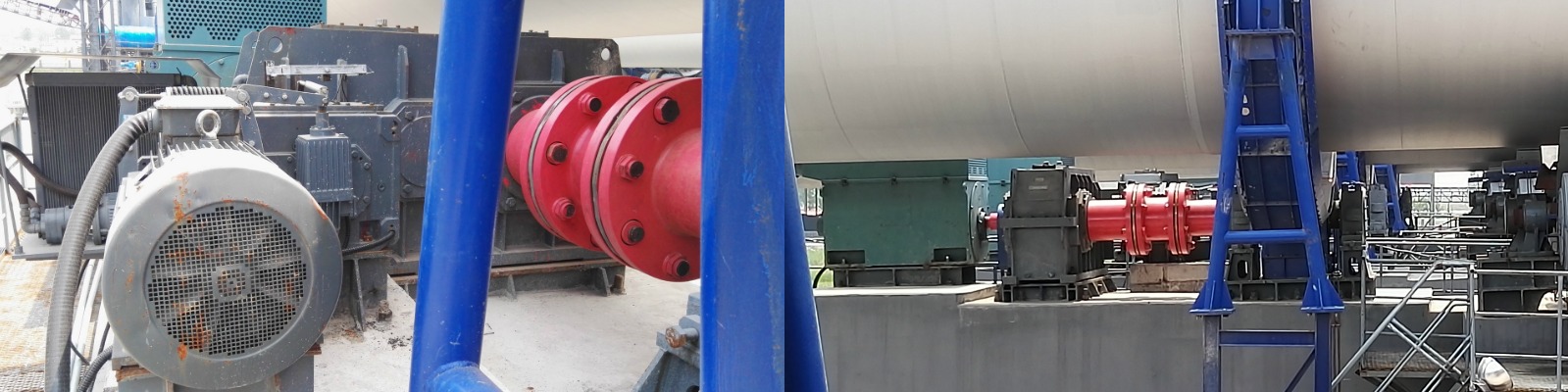

Rotary Kiln Drive

Zonpoo rotary kiln drive is the core of lime and cement clinker production.

In the slightly inclined cylindrical tube, which rotates around its longitudinal axis during the firing process and burned into cement clinker.

The rotation has both a transport and an air injection effect. The length a kiln can be more than 100 meters.

In this type of kiln, the limestone is added at the slightly higher end and slowly passes through the kiln due to the rotation. All drive elements must also be inclined accordingly.

Zonpoo offers the latest drive systems for rotary kilns: frequency controlled electric motors, Zonpoo helical, bevel helical, and planetary gear units, auxiliary gear units with integral overrunning clutch and centrifugal brake, holding brake, auxiliary motor.

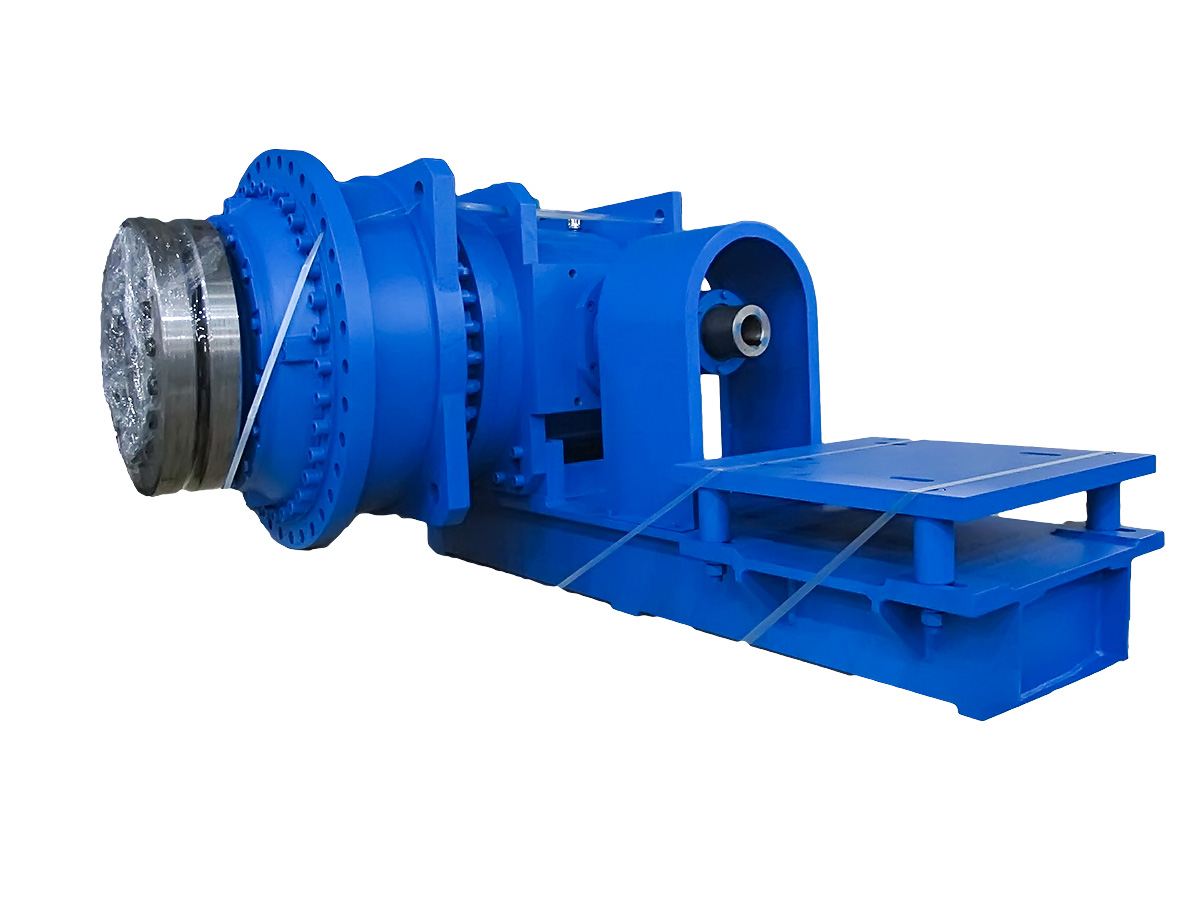

Suitable Zonpoo gear unit types

- Zonpoo H series helical gear units

- Zonpoo B series bevel helical gear units

- Zonpoo planetary gear units

Why Zonpoo rotary kiln drive

- H series helical gear unit and bevel-helical gear unit

- Robust gear unit housing

- Compact, space-saving design

- Lubrication system

- Drive pinion and pedestal bearing, if required

- Segmented girth gear with bolted spring plates

- Girth gear manufactured from austempered ductile iron

- Auxiliary drive mounted on the side of the main gear unit

- Gear units, torque arm, motors, couplings, brakes, cooling systems are supplied ready for installation